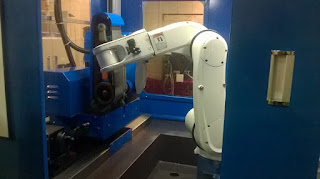

Industrial machinery, application of hand

Manipulator in the mechanization and

automation of the production process developed a new type of device.,cnc milling machine In recent

years, as electronic technology, especially computer extensive use of robot

development and production of

high-tech fields has become a rapidly

developed a new technology, which further promoted the development of robot,

allowing robot to better achieved with the combination of mechanization and

automation.

Although the robot is not as flexible as

staff, but it has to the continuous duplication of work and labor, I do not

know fatigue, not afraid of danger, the power snatch weight characteristics

when compared with manual large, therefore, mechanical hand has been of great

importance to many sectors, and increasingly has been applied widely, for

example:

(1)

Machining the workpiece loading and unloading, especially in the automatic

lathe, combination machine tool use is more common.

(2) In the assembly operations are widely

used in the electronics industry, it can be used to assemble printed circuit

boards, in the machinery industry It can be used to assemble parts and

components.

(3) The working conditions may be poor,

monotonous, repetitive easy to sub-fatigue working environment to replace human

labor.

(4)

May be in dangerous situations, such as military goods handling, dangerous

goods and hazardous materials removal and so on.

(5) Universe and ocean development.

(6),

military engineering and biomedical research and testing. Help mechanical hands: also known as the

balancer, balance suspended, labor-saving spreader, manual Transfer machine is

a kind of weightlessness of manual load system, a novel, time-saving technology

for material handling operations booster equipment, belonging to kinds of

non-standard design of series products. Customer application needs, creating

customized cases. Manual operation of a simulation of the automatic machinery,

it can be a fixed program draws ﹑ handling

objects or perform household tools to accomplish certain specific actions.

Application of robot can replace the people engaged in monotonous ﹑ repetitive or heavy manual labor, the mechanization and automation

of production, instead of people in hazardous environments manual operation,

improving working conditions and ensure personal safety.

The late 20th century, 40, the United

States atomic energy experiments, the first use of radioactive material

handling robot, human robot in a safe room to manipulate various operations and

experimentation. 50 years later, manipulator and gradually extended to

industrial production sector, for the temperatures, polluted areas, cnc milling machine and loading

and unloading to take place the work piece material, but also as an auxiliary

device in automatic machine tools, machine tools, automatic production lines

and processing center applications, the completion of the upper and lower

material, or From the library take place knife knife and so on according to

fixed procedures for the replacement operation. Robot body mainly by the hand

and sports institutions. Agencies with the use of hands and operation of

objects of different occasions, often there are clamping ﹑ support and adsorption type of care. Movement organs are generally

hydraulic pneumatic ﹑ ﹑ electrical device drivers.

Manipulator can be achieved independently

retractable ﹑ rotation and lifting

movements, generally 2 to 3 degrees of freedom. Robots are widely used in

metallurgical industry, machinery manufacture, light industry and atomic energy

sectors. Can mimic some of the staff and

arm motor function, a fixed procedure for the capture, handling objects or

operating tools, automatic operation device. It can replace human labor in

order to achieve the production of heavy mechanization and automation that can

operate in hazardous environments to protect the personal safety, which is

widely used in machinery manufacturing, metallurgy, electronics, light industry

and nuclear power sectors. Mechanical hand tools or other equipment commonly

used for additional devices, such as the automatic machines or automatic

production line handling and transmission of the workpiece, the replacement of

cutting tools in machining centers, etc. generally do not have a separate

control device. Some operating devices require direct manipulation by humans;

such as the atomic energy sector performs household hazardous materials used in

the master-slave manipulator is also often referred to as mechanical hand.

Manipulator mainly by hand and sports

institutions. Task of hand is holding the workpiece (or tool) components,

according to grasping objects by shape, size, weight, material and operational

requirements of a variety of structural forms, such as clamp type, type and

adsorption-based care such as holding. Sports organizations, so that the

completion of a variety of hand rotation (swing), mobile or compound movements

to achieve the required action, to change the location of objects by grasping

and posture. Robot is the automated production of a kind used in the process of

crawling and moving piece features automatic device, which is mechanized and

automated production process developed a new type of device. In recent years,

as electronic technology, especially computer extensive use of robot

development and production of high-tech fields has become a rapidly developed a

new technology, which further promoted the development of robot, allowing robot

to better achieved with the combination of mechanization and automation. Robot

can replace humans completed the risk of duplication of boring work, to reduce

human labor intensity and improve labor productivity. Manipulator has been

applied more and more widely, in the machinery industry, it can be used for

parts assembly, work piece handling, loading and unloading, particularly in the

automation of CNC machine tools, modular machine tools more commonly used.

At present, the robot has developed into a

FMS flexible manufacturing systems and flexible manufacturing cell in an

important component of the FMC. The machine tool equipment and machinery in

hand together constitute a flexible manufacturing system or a flexible

manufacturing cell, it was adapted to small and medium volume production, you

can save a huge amount of the work piece conveyor device, compact, and

adaptable.cnc milling machine When the work piece changes, flexible production system is very easy

to change will help enterprises to continuously update the marketable variety,

improve product quality, and better adapt to market competition.

At present, China's industrial robot

technology and its engineering application level and comparable to foreign

countries there is a certain

distance, application and industrialization

of the size of the low level of robot research and development of a direct

impact on raising the level of automation in China, from the economy, technical

considerations are very necessary. Therefore, the study of mechanical hand

design is very meaningful.