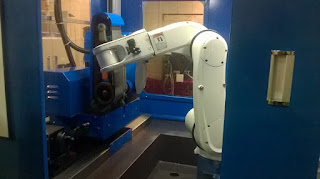

Manipulator

Robot developed in recent decades as high-tech automated production equipment. Industrial robot is an important

branch of industrial robots. It features can be programmed to perform tasks in

a variety of expectations, Cnc machining in both structure and performance advantages of

their own people and machines, in particular, reflects the people's

intelligence and adaptability. The accuracy of robot operations and a variety

of environments the ability to complete the work in the field of national economy

and there are broad prospects for development. With the development of

industrial automation, there has been CNC machining center, it is in reducing

labor intensity, while greatly improved labor productivity. However, the upper

and lower common in CNC machining processes material, usually still use manual

or traditional relay-controlled semi-automatic device. The former

time-consuming and labor intensive, inefficient; the latter due to design

complexity, require more relays, wiring complexity, vulnerability to body

vibration interference, while the existence of poor reliability, fault more

maintenance problems and other issues. Programmable Logic Controller

PLC-controlled robot control system for materials up and down movement is

simple, circuit design is reasonable, with a strong anti-jamming capability, Cnc machining ensuring the system's reliability, reduced maintenance rate, and improve work

efficiency. Robot technology related to mechanics, mechanics, electrical

hydraulic technology, automatic control technology, sensor technology and

computer technology and other fields of science, is a cross-disciplinary

integrated technology.

First, an overview of industrial manipulator

Robot is a kind of positioning control can be automated and can be

re-programmed to change in multi-functional machine, which has multiple degrees

of freedom can be used to carry an object in order to complete the work in

different environments. Low wages in industry, although still a

labor-intensive, mechanical hand use has become increasingly popular.

Electronics and automotive industries that Europe and the United States

multinational companies very early in their factories in China, the

introduction of automated production. But now the changes are those found in

industrial-intensive South China, East China's coastal areas, local plastic

processing plants have also emerged in mechanical watches began to become

increasingly interested in, because they have to face a high turnover rate of

workers, as well as for the workers to pay work-related injuries fee

challenges.China, plastic products .

With

the rapid development of China's industrial production, especially the reform

and opening up after the rapid increase in the degree of automation to achieve

the workpiece handling, steering, transmission or operation of brazing, spray

gun, wrenches and other tools for processing and assembly operations since,

which has more and more attracted our attention. Robot is to imitate the manual

part of the action, according to a given program, track and requirements for

automatic capture, handling or operation of the automatic mechanical devices.

In

real life, you will find this a problem. In the machine shop, the processing of

parts loading time is not annoying, and labor productivity is not high, the

cost of production major, and sometimes man-made incidents will occur,

resulting in processing were injured. Think about what could replace it with

the processing time of a tour as long as there are a few people, and can

operate 24 hours saturated human right? The answer is yes, but the robot can

come to replace it

Production of mechanical hand can increase the

automation level of production and labor productivity; can reduce labor

intensity, ensuring product quality, to achieve safe production; particularly

in the high-temperature, high pressure, low temperature, low pressure, dust,

explosive, toxic and radioactive gases such as poor environment can replace the

normal working people. Here I would like to think of designing a robot

to

be used in actual production.

Why

would a robot designed to provide a pneumatic power: pneumatic robot refers to

the compressed air as power source-driven robot.

With

pressure-driven and other energy-driven comparison have the following

advantages: 1. Air inexhaustible, used

later discharged into the atmosphere, does not require recycling and disposal,

do not pollute the environment. (Concept of environmental protection)

2. Air stick is small, the pipeline

pressure loss is small (typically less than asphalt

path

pressure drop of one-thousandth), to facilitate long-distance transport.

3. Compressed air of the working pressure

is low (usually 4 to 8 kg / per square centimeter), and therefore moving the

material components and manufacturing accuracy requirements can be lowered.

4. With the hydraulic transmission,

compared to its faster action and reaction, which is one of the advantages

pneumatic outstanding.

5. The air cleaner media, it will not

degenerate, not easy to plug the pipeline.

But there are also places where it fly in

the ointment:

1.

As the compressibility of air, resulting in poor aerodynamic stability of the

work, resulting in the implementing agencies as the precision of the velocity

and not easily controlled.

2.

As the use of low atmospheric pressure, the output power can not be too large;

in order to increase the output power is bound to the structure of the entire

pneumatic system size increased.

With pneumatic drive and compare with other energy sources drive has the

following advantages: Air inexhaustible,

used later discharged into the atmosphere, without recycling and disposal, do

not pollute the environment. Accidental or a small amount of leakage would not

be a serious impact on production.

Viscosity of air is small, the pipeline pressure loss also is very

small, easy long-distance transport.

The

lower working pressure of compressed air, pneumatic components and therefore

the material and manufacturing accuracy requirements can be lowered. In

general, reciprocating thrust in 1 to 2 tons pneumatic economy is better.

Compared with the hydraulic transmission, and its faster action and

reaction, which is one of the outstanding merits of pneumatic. Clean air medium, it will not degenerate, not

easy to plug the pipeline. It can be safely used in flammable, explosive and

the dust big occasions. Cnc machining Also easy to realize automatic overload protection.

没有评论:

发表评论