Automatic Fixture Design

Precisionmetal parts Assembly equipment used in the traditional

synchronous fixture put parts of the fixture mobile center, to ensure that

components from transmission from the plane or equipment plate placed after

removal has been scheduled for position. However, in certain applications,

mobile mandatory parts of the center line, it may cause parts or equipment

damage. When parts vulnerability and may lead to a small vibration abandoned,

or when their location is by machine spindle or specific to die, Tolerance

again or when the request is a sophisticated, it would rather let the fixture

to adapt to the location of parts, and not the contrary. For these tasks,

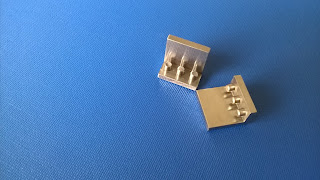

Elyria, Ohio, the company has developed Zaytran a general non-functional data

synchronization West category FLEXIBILITY fixture. Fixture because of the

interaction and synchronization devices is independent, The synchronous device

can use sophisticated equipment to replace the slip without affecting the

fixture force. Fixture specification range from 0.2 inches itinerary, 5 pounds

clamping force of the six-inch trip, 400-inch clamping force.

Precisionmetal parts The characteristics of

modern production is becoming smaller and smaller quantities and product

specifications biggest changes. Therefore, in the final stages of production,

assembly of production, quantity and product design changes appear to be

particularly vulnerable. This situation is forcing many companies to make

greater efforts to rationalize the extensive reform and the previously

mentioned case of assembly automation. Despite flexible fixture behind the

rapid development of flexible transport and handling devices, such as backward

in the development of industrial robots, it is still expected to increase the

flexibility fixture. In fact the important fixture devices -- the production of

the devices to strengthen investment on the fixture so that more flexibility in

economic support holders.

According to their flexibility and fixture can

be divided into : special fixture, the fixture combinations, the standard

fixture, high flexible fixture. Flexible fixture on different parts of their

high adaptability and the few low-cost replacement for the characteristic.

Forms can transform the structure of the flexible fixture can be

installed with the change of structure components (such as needle cheek plate,

Multi-chip components and flake cheek plate), a non-standard work piece gripper

or clamping elements (for example : commencement standard with a clamping

fixture and mobile components fixture supporting documents), or with ceramic or

hardening of the intermediary substances (such as : Mobile particle bed fixture

and heat fixture tight fixture). To production, the parts were secured fixture,

the need to generate clamping function, its fixture with a few unrelated to the

sexual submissive steps :

According to the processing was part of that

foundation and working characteristics to determine the work piece fixture in

the required position, then need to select some stability flat combination,

These constitute a stable plane was fixed in the work piece fixture set

position on the clamp-profile structure, all balanced and torque, it has also

ensured that the work features close to the work piece. Finally, it must be

calculated and adjusted, assembly or disassembly be standard fixture components

required for the position, so that the work piece firmly by clamping fixture in

China. In accordance with this procedure, the outline fixture structure and

equipped with the planning and recording process can be automated control.

Structural modeling task is to produce some stable flat combination,

Thus, these plane of the work pieces clamping force and will fixture stability.

According to usual practice, this task can be human-machine dialogue that is

almost completely automated way to completion. A man-machine dialogue that is

automated fixture structure modeling to determine the merits can be conducted

in an organized and planning fixture design, reduce the amount of the design,

shortening the study period and better distribution of work conditions. In

short, can be successfully achieved significantly improve fixture efficiency

and effectiveness.

Precisionmetal parts Fully prepared to structure programs and the number of material

circumstances, the completion of the first successful assembly can save up to

60% of the time. Therefore fixture

process modeling agencies is the purpose of the program have appropriate.

没有评论:

发表评论