The numerical control transformation

superiorly lacks

Reduced investment costs, the date of delivery

are short

With purchases the new engine bed to compare, may save 60% ~ 80% expense

generally, the transformation expense is low. Large-scale, the special engine

bed especially is specially obvious. The common large-scale engine bed

transforms, Cnc machining only spends the

new engine bed purchase

expense 1/3, the date of delivery is short.

But some peculiar circumstances, like the high speed main axle, the tray automatic

switching unit manufacture and the installment too requires a lot of work,

costs a great deal of money, often transforms the cost to enhance 2 ~ 3 times,

with purchases the new engine bed to compare, only can economical invest about

50%.

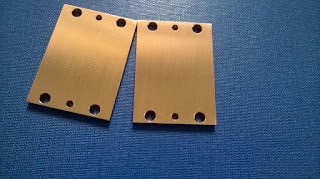

Machine capability stable are reliable, the structure is limited

Uses foundation and so on lathe bed, column all is heavy but the firm

casting component, but is not that kind of welding component, after the

transformation engine bed performance high, the quality is good, may take the

new equipment continues to use many years. But receives the original mechanism

the limit, not suitably makes the unprecedented transformation.

Familiar understood the equipment, is advantageous for the operation

service

When

purchases the new equipment, did not understand whether the new equipment can

satisfy its processing request. Cnc machiningThe

transformation then otherwise, may precisely calculate the engine bed the

processing ability; Moreover, because many years use, the operator already

understood to the engine bed characteristic, uses and services the aspect to

train the time in the operation short, effective is quick. The transformation

engine bed as soon as installs, may realize the capacity load revolution.

May

fully use the existing condition

May

fully use the existing ground, Cnc machining does

not need to like buys when the new equipment such to have reto construct the

ground.

May

use the newest control technology

enhances the production equipment the

automated level and the efficiency, improves the equipment quality and the

scale, alters to the old engine bed now the horizontal engine bed.