Die Casting

Die casting involves the preparation of components by injecting molten

metal at high pressures into a metallic die.China CNC machining Die casting is closely related to

permanent mould casting, in that both the processes use reusable metallic dies.

In die casting, as the metal is forced in under pressure compared to permanent

moulding, it is also called pressure die casting'. Because of the high pressure

involved in die casting, any narrow sections, complex shapes and fine surface

details can be easily produced.

In die casting, the die consists of two parts. One called the stationary

die or cover die which is fixed to the die casting machine. China CNC machining The second part

called the ejector die is moved out for the extraction of the casting. The

casting cycle starts when the two parts of the die are apart. The lubricant is

sprayed on the die cavity manually or by the auto lubrication system. The two

die halves are closed and clamped. The required amount of metal is injected

into the die. After the casting is solidified under pressure the die is opened

and the casting is ejected.

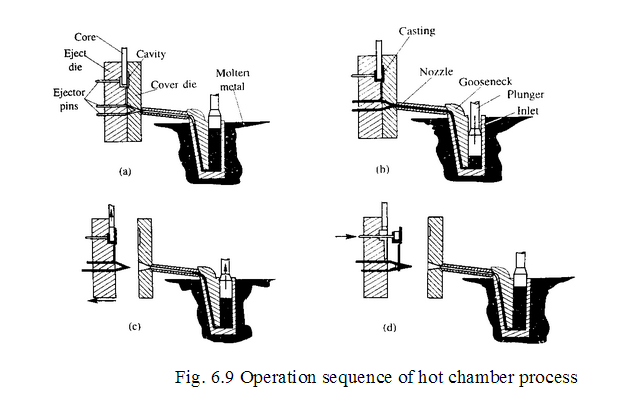

The die casting machines are of two types: hot chamber die casting, and

cold chamber die casting. The main difference between these two types is that

in hot chamber, the holding furnace for the liquid metal is integral with the

die casting machine, whereas in the cold chamber machine, China CNC machining the metal is melted

in a separate furnace and then poured into the die casting machine with a ladle

for each casting cycle which is also called 'shot'.

没有评论:

发表评论