Squeeze Casting and Lost Foam Casting

Squeeze China precision machining casting also known as liquid metal forging, is a combination of

casting and forging process The molten

metal is poured into the bottom half of the pre-heated die. As the metal starts

solidifying, the upper half closes the die and applies pressure during the

solidification process. The amount of pressure thus applied is significantly

less than used in forging, and parts of great detail can be produced.

Coring can be used with this process to form

holes and recesses. The porosity is low and the mechanical properties are

improved. Both ferrous and non-ferrous materials can be produced using this

method.

Fig.

6.12 Schematic of squeeze casting process

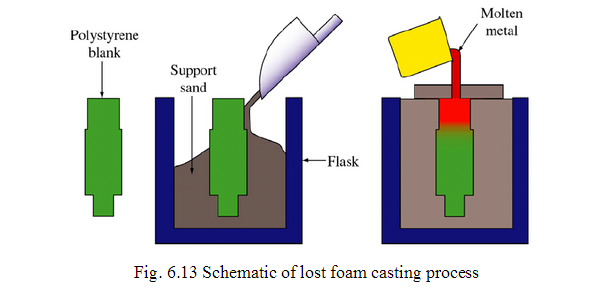

Lost

Foam Casting

Lost foam casting allows the production of complex parts. The process

produces complex parts and reduces finish machining of the part produced by

lost foam casting.

To

make lost foam casting, a foam pattern of the finished part is made.

The

pattern is dipped into a water solution containing a suspended refractory. The refractory material coats the foam

pattern leaving a thin heat resistant layer. Sand is poured around the pattern

and provides mechanical support to the thin refractory layer. 。 Molten metal is then poured

into the mold, and the molten metal melts and vaporizes the foam. When the

metal becomes solid, it is removed from the sand, thus the name lost foam

casting. Lost foam castings may be of

any shape or size. Materials commonly used in lost foam casting are Aluminum,

iron, steel and nickel alloys. The Lost

Foam casting process originated in 1958 when H.F. Shroyer was granted a patent

for a cavity-less casting method,China precision machining using a polystyrene foam pattern embedded in

traditional green sand.

The polystyrene foam pattern left in the sand is decomposed by the

poured molten metal. The metal replaces

the foam pattern, exactly duplicating all of the features of the original

pattern. Like other investment casting

methods, this requires that a pattern be produced for every casting poured

because it is evaporated (“lost”) in the process.

The basic steps to the process include

(Fig. 6.13):

1. A

foam pattern and gating system are made using a foam molding press

2. The foam pattern and the gating system

are glued together to form a cluster of patterns

3.

The cluster is coated with a permeable refractory coating and dried under

controlled conditions

4. The dried, coated cluster is invested in

a foundry flask with loose, unbonded sand that is vibrated to provide tight

compaction

5. The molten metal is poured on to the top

of the gating system which directs the metal throughout the cluster and

replaces the foam gating and patterns

6. The remaining operations such as, shake

out, cut-off,

grinding, heat treat, etc. are

straightforward and similar to other casting processes.

Fig. 6.13 Schematic of lost foam casting

process

Generally, all ferrous and non-ferrous

materials can be successfully cast using the Lost Foam process. Because the foam pattern and gating system

must be decomposed to produce a casting, metal pouring temperatures above

1000°F are usually required. Lower temperature metals can be poured, but part

size is limited. China precision machining In addition, very low

carbon ferrous castings will require special processing.

没有评论:

发表评论