Centrifugal Casting

China metal parts machining Centrifugal casting consists of having sand, metal, or ceramic mold that

is rotated at high speeds. When the molten metal is poured into the mold it is

thrown against the mold wall, where it remains until it cools and solidifies.

The process is being increasingly used for such products as cast-iron pipes,

cylinder liners, gun barrels, pressure vessels, brake drums gears, and

flywheels. The metals used include almost all castable alloys. Because of the

relatively fast cooling time, centrifugal castings have a fine gram size. There

is a tendency for the lighter non-metallic inclusions slagparticles, and dross

to segregate toward the inner radius of the casting where it can be easily

removed by machining. Due to the high purity of the outer skin, centrifugally

cast pipes have a high resistance to atmospheric corrosion.

The principle of centrifugal casting is shown

as Fig. 11.11. The centrifugal force produced by rotation is large compared

with normal hydrostatic forces and is utilized in two ways. The first of these

is seen in pouring, where the force can be used to distribute liquid metal over

the outer surfaces of a mould. This provides a means of forming hollow

cylinders and other annular shapes. The second is the development of high

pressure in the casting during freezing. This, in conjunction with directional

solidification, assists feeding and accelerates the separation of non-metallic

inclusions and precipitated gases. The advantages of the process are therefore

twofold: suitability for casting cylindrical forms and high metallurgical

quality of the product.

The casting China metal parts machining of a plain pipe or tube is accomplished by rotation of a

mould about its own axis, the bore shape being produced by centrifugal force

alone and the wall thickness determined by the volume of metal introduced. This

practice is widely referred to as true centrifugal casting. In

the case of a component of varying internal

diameter or irregular wall thickness a central core may be used to form the

internal contours, feeder heads then being introduced to compensate for

solidification shrinkage. A further step away from the original concept is the

spacing of separate shaped castings about a central down-runner, which forms

the axis of rotation. These variations are referred to respectively as

semicentrifugal casting and centrifuging or pressure casting; in both cases,

since the castings are shaped wholly by the mould and cores, centrifugal force

is used primarily as a source of pressure for feeding.

The rotational axis may be horizontal,

vertical or inclined and important variations exist in respect of mould

material and the method of introduction of the molten metal.

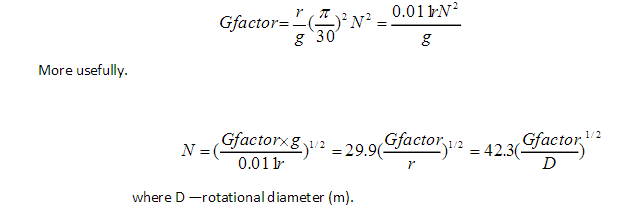

The centrifugal force acting upon a rotating body is proportional to the

radius of rotation and to the square of the velocity:

The

gravitational force on the same mass would be given by:

Hence the

factor by which the normal force of gravity is multiplied during rotation is

given by:

Expressed in the

more convenient speed units of revolutions per minute, N, the expression

becomes:

Although centrifugal forces exceeding 200G are attained in some cases,

most practice is empirically based within the range 10-150G, the highest values

being used for open bore cylindrical components of small diameter and the

lowest for semicentrifugal and pressure castings. Speeds generating forces of

60-80G are most commonly quoted for true centrifugal castings. As previously

emphasized, however, the optimum value of centrifugal force diminishes with

increasing diameter.

Cumberland quotes values of 33G for a wide range of plain vertical axis

castings and 15G for semi-centrifugal castings in sand moulds, for which lower

speeds suffice since there is no longer dependence on centrifugal force to

shape the casting. Thornton gives values of 50-100G for die cast and 25-50G for

sand castpots and shaped castings.

This is a process where the mould is rotated rapidly about its central

axis as the metal is poured into it. Because of the centrifugal force, a

continuous pressure will be acting on the metal as it solidifies. The slag,

oxides and other inclusions being lighter, get separated from the metal and

segregates toward the centre. China metal parts machining There are three main types of centrifugal casting

processes. They are: true centrifugal casting, semi-centrifugal casting,

centrifuging.

没有评论:

发表评论