The material properties

The material properties can be classified

into three major headings:

(i) Physical,

(ii) Chemical,

(iii) Mechanical. Physical properties

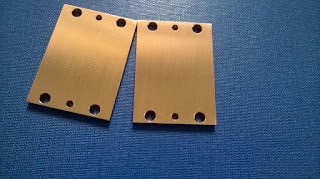

Precision CNC machining parts Density

or specific gravity, moisture content, etc., can be classified under this category. Chemical properties

Precision CNC machining parts Many

chemical properties come under this category. These include acidity or

alkalinity, reactivity and corrosion. The most important of these is corrosion

which can be explained in layman’s terms as the

resistance of the material to decay while in continuous use in a

particular atmosphere.

Precision CNC machining parts Mechanical

properties Mechanical properties include the strength properties

like tensile, compression, shear,

torsion, impact, fatigue and creep. The tensile strength of a material

is obtained by dividing the maximum load, which the specimen bears by the area

of cross-section of the pecimen. This is a curve plotted between the stress along the

Y-axis(ordinate) and the strain along the X-axis(abscissa) in a tensile test. A

material tends to change or changes its dimensions when it is loaded, depending

upon the magnitude of the load. When the load is removed it can be seen that

the deformation disappear s. For many materials this occurs up to a certain

value of the stress called the elastic limit. This is depicted by the straight

line relationship and a small deviation thereafter, in the stress-strain curve.

没有评论:

发表评论