Boosting Competitiveness

As

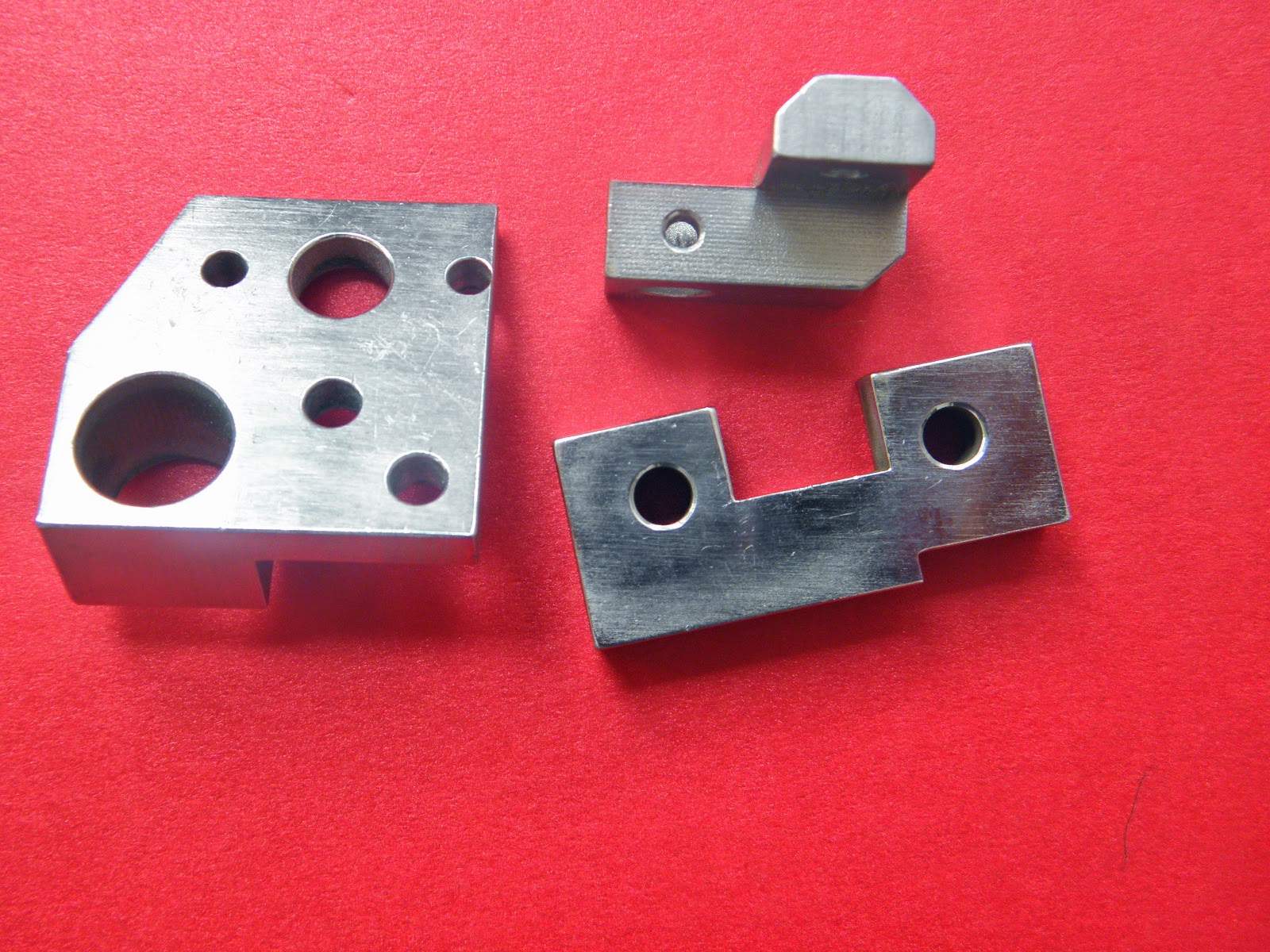

mentioned, robotic China metal parts machining applications originated in the automotive industry. General

Motors, with some 40-50,000 robots, continues to utilize and develop new

approaches. The ability to bring more intelligence to robots is now providing

significant new strategic options. Automobile prices have actually declined

over the last two to three years, so the only way that manufacturers can

continue to generate profits is to cut structural and production costs.

When plants are converted to new automobile models, hundreds of millions

of dollars are typically put into the facility. The focus of robotic

manufacturing technology is to minimize the capital investment by increasing

flexibility. New robot applications are being found for operations that are

already automated with dedicated equipment. Robot flexibility allows those same

automated operations to be performed more consistently, with inexpensive

equipment and with significant cost advantages.

Robotic Assistance

A

key robotics growth arena is Intelligent Assist Devices (IAD).operators

manipulate a robot as though it were a bionic extension of their own limbs with

increased reach and strength. This is robotics technology not replacements for

humans or robots, but rather a new class of ergonomic assist products that

helps human partners in a wide variety of ways, including power assist, motion

guidance, line tracking and process automation.

IAD

use robotics technology to help production people to handle parts and payloads,

more, heavier, better, faster,China metal parts machining with less strain. Using a human-machine

interface, the operator and IAD work in tandem to optimize lifting, guiding and

positioning movements. Sensors, computer power and control algorithms translate

the operator's hand movements into super human lifting power.

New robot configurations

As

the technology and economic implications of Moore's law continue to shift

computing power and price, we should expect more innovations, more

cost-effective robot configurations, more applications beyond the traditional

service emphasis.

The

biggest change in industrial robots is that they will evolve into a broader

variety of structures and mechanisms. In many cases, configurations that evolve

into new automation systems won't be immediately recognizable as robots. For

example, robots that automate semiconductor manufacturing already look quite

different from those used in automotive plants.

We

will see the day when there are more of these programmable tooling kinds of

robots than all of the traditional robots that exist in the world today. There

is an enormous sea change coming; the potential is significant because soon

robots will offer not only improved cost-effectiveness, but also China metal parts machining advantages and

operations that have never been possible before.

没有评论:

发表评论